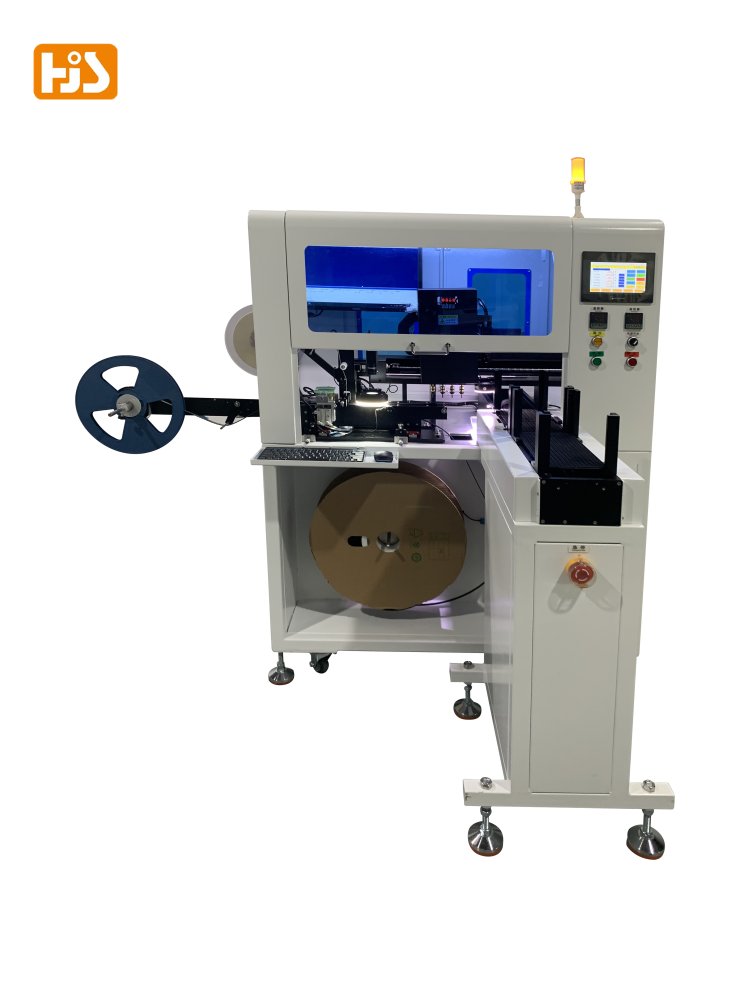

JEDEC Tray Tape and Reel Equipment HJC-009TR

Name: Automatic Tape and Reel Machine for JEDEC Tray Feeding HJC-009TR/ JEDEC tray tape and reel machine for IC components

Model: HJC-009TR

Use: Auto tray feeding, nozzle pick component from tray and place into carrier tape;

Tray can be JEDEC standard or customized size only if frame outsize is unified.

semiconductor tape and reel equipment| jedec tray tape and reel|jedec tray packaging|tape and reel vs tray|tape and reel packaging|tray packaging|jedec tray standards

Features:

1. Auto tray system, which can hold 20~30 trays;

2. Four nozzles, each nozzle independently controlled for rotate; With CCD detect orientation, nozzle can rotate to correct component orientation;

3. CCD final inspection before sealing to ensure corrent component position;

4. Pick and place speed can be adjusted with HMI menu;

Application: The machine realizes automatic taping with component tray feeding(tray size: 323 * 136mm), including automatic tray sending, automatic tray receiving, automatic component picking, automatic component filling (100%), automatic carrier tape uploading, automatic cover tape loading, automatic sealing, material leakage detection, automatic counting, alarm and emergency stop, etc.

Standard JEDEC tray sample(Other tray size need sample for confirmation):

Feeding method: tray feeding

Sealing method: Cold seal / heat seal optional

Sealing peel force: 20~150g adjustable

Machine capacity: 3~5kpcs / h (depending on product size);

Applicable products: inductor (integrated series, NR Series);

Operation control mode: PLC+HMI touch screen;

Working environment: 10 ℃ ~ 40 ℃

Heating temperature: 0 ℃ ~ 200 ℃

CCD image detection: Optional

Machine size: L1400 x W800x H1700mm;

Power supply: AC220V, 50Hz;

Air pressure: 5KG/CM³;

Power: 1000W;

Overall weight: About 500kg;

Options:

- Machine can be 1~4 nozzles configured;

- Machine structure can be modified for in-line production;