CATEGORIES

Equipment

Comsumables

CONTACT

sabrina.he@hjsautomation.com

+86 15989403900

+86 15989403900

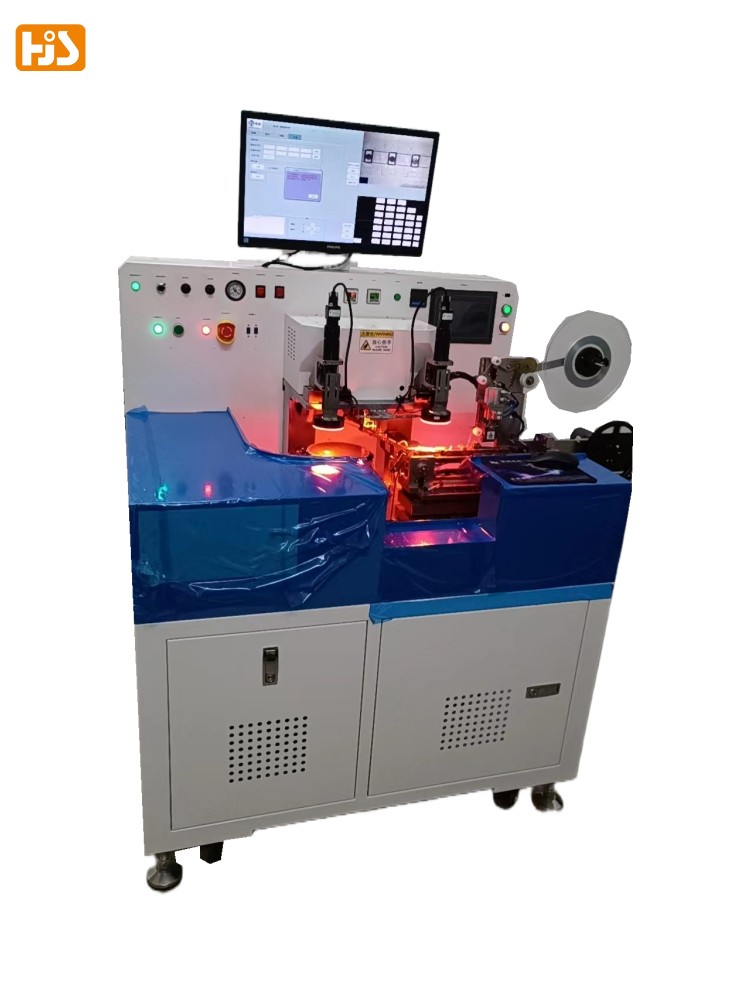

Wafer Pick and Place Machine HJC-560

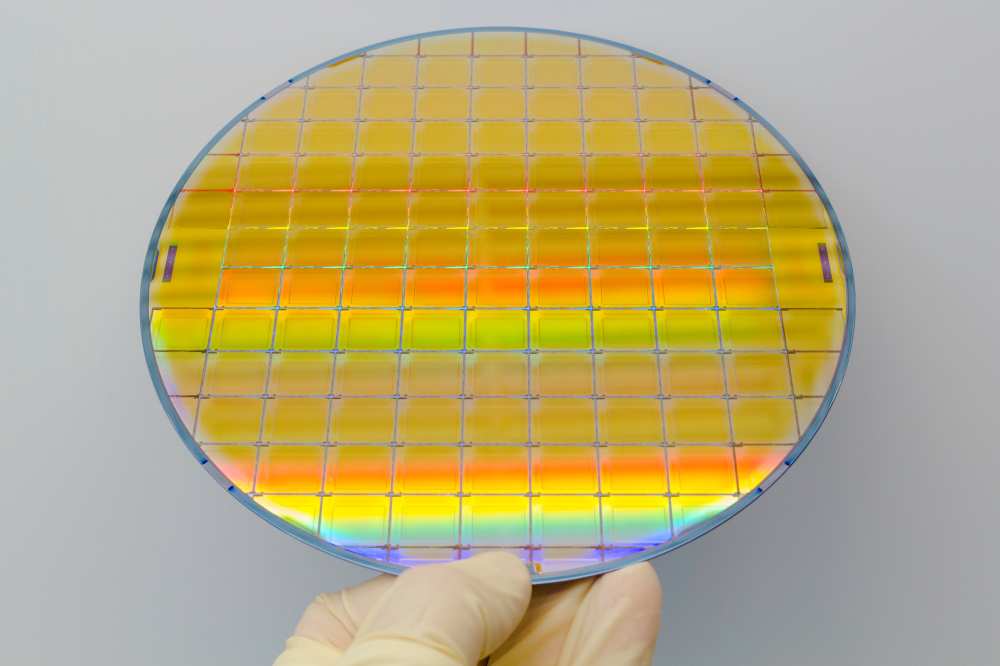

1. Can be used with 6-inch/8-inch Wafer ring input and tape&reel output;

2. Pick with one nozzle from wafer ring to carrier tape;

3. Mapping function is optional;

4. For 1.0 × 1.0 (mm) to 12 × 12 (mm) size die;

5. Suitable for QFN, CSP etc;

6. Carrier tape rail width fixed. One machine is for one spec carrier tape only;

7. HMI software has English language

Wafer to dicing tape|wafer tape and reel|bare die tape and reel machine|die sorting machine|wafer to waffle tray|die bonding|wafer pick and place|die sorting machine|wafer handling and pick-and-place|semiconductor die sorting|die pick and place machine|die inspection and sorting|wafer handling and pick-and-place

|

Contents |

Parameters |

|

Machine overall size |

1300×1200×1650 (L×W×H) |

|

Input voltage |

AC 220V 50Hz |

|

Maximum power |

3KW |

|

Weight |

800KG |

|

Input air supply pressure |

0.4~0.7 Mpa |

|

Air pressure consumption |

≈50~120L/min |

|

UPH |

≥2000Pcs/H (CT≥1.2 S) |

|

Swing yield |

≥99% |

|

Mechanism positioning accuracy |

XY axis ± 0.01mm, rotation axis ± 0.05 ° |

|

Operation mode |

Manual loading and unloading, automatic reclaiming and swinging |

|

Material conveying mode |

Linear motor |

|

Control mode |

Integrated control |

|

Startup mode |

Button start |

|

Parameter setting mode |

Screen settings |

|

Abnormal alarm mode |

Buzzer+screen display+three color indicator |

Options:

- can be from wafer to wafer, wafer to JEDEC tray/waffle tray, wafer to tape&reel.

- can be used with mapping file

- other function can be customized

please contact sales for more video